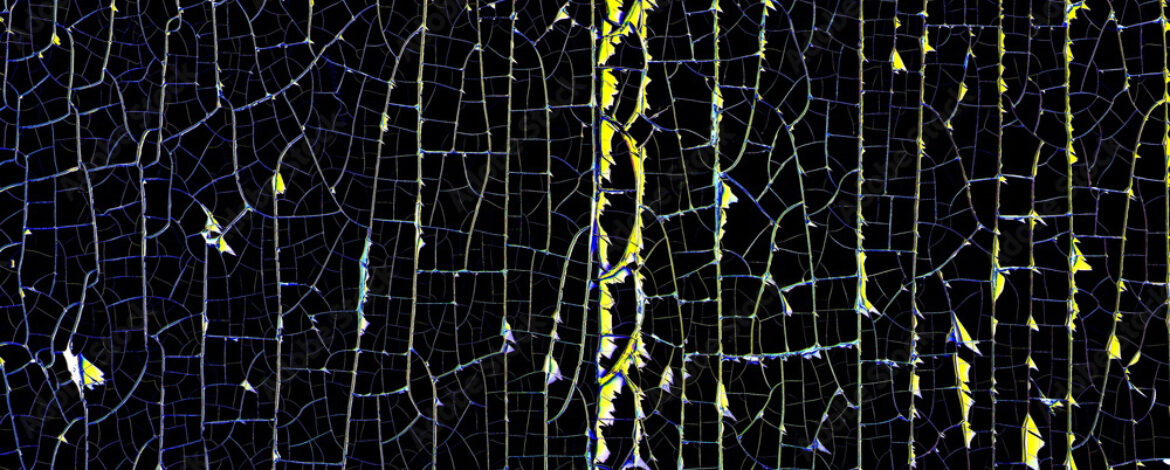

Wood coverings, surfaces, laminates, plastic materials undergo ageing phenomena, which may affect their surface finishes going to impact: on the aesthetics, durability and strength of the furniture of which they are part.

Exposure to light, heat and moisture are among the most common causes of deterioration of the products in terms of loss of brilliance, discoloration, cracking up to delamination and loss of resistance.

How are these performances assessed?

Accelerated ageing and light fastness tests recreate the particular environmental conditions and therefore the effects that could occur as a result of excessive or prolonged exposure to sunlight or external atmospheric agents for this reason are widely used for research and development, quality control and material certification.

These tests are performed with two types of machinery: the one that uses UV fluorescent lamps and the one that uses xenon arc lamps. With both machines it is possible to perform the main test methods (national and international): which allow to verify the behavior of painting, galvanizing and surface protection treatments in general, simulating relatively quickly what would happen after months or years of exposure to normal atmospheric conditions, including sunlight and other atmospheric agents such as rain, fog and humidity.

The Q-SUN instrument: realistic, precise and versatile

The COSMOB laboratory uses the xenon lamp chamber Q-SUN Xe-3, because it is designed not only by taking into account its ability to accurately reproduce environmental conditions and light exposure to induce potential damage that could occur over months or years in just a few days or weeks, but also for its ease of use, maintenance and calibration.

The COSMOB laboratory uses the xenon lamp chamber Q-SUN Xe-3, because it is designed not only by taking into account its ability to accurately reproduce environmental conditions and light exposure to induce potential damage that could occur over months or years in just a few days or weeks, but also for its ease of use, maintenance and calibration.

A machine that we at COSMOB do not hesitate to define:

REALISTIC: the almost horizontal sample tray of the Q-SUN allows moisture to remain on the sample surface for a longer time and to simulate the natural environmental conditions in which many products will actually find themselves in reality;

PRECISE: the Q-SUN chamber can expose the samples to the equivalent of summer sunlight at noon for 24 hours a day, every day; consequently, the degradation of the sample can be very accelerated as it is subjected to “extreme” light exposure conditions;

VERSATILE: the instrument is able to accommodate samples with different shapes, sizes and types, even three-dimensional, so as to meet different types of requirements.

Thanks to the Q-SUN instrument, the COSMOB Testing Laboratory is able to perform accelerated ageing tests on different types of materials such as coated and laminated panels, accessories as well as outdoor furniture such as fixed or removable benches: for which the latter tests are of greater importance as they are more exposed to atmospheric events.

For more information:

Dott. Christian Gabbani

Chemical Department Manager – Quality Test Laboratory

FabLab Department Manager

c.gabbani@cosmob.it